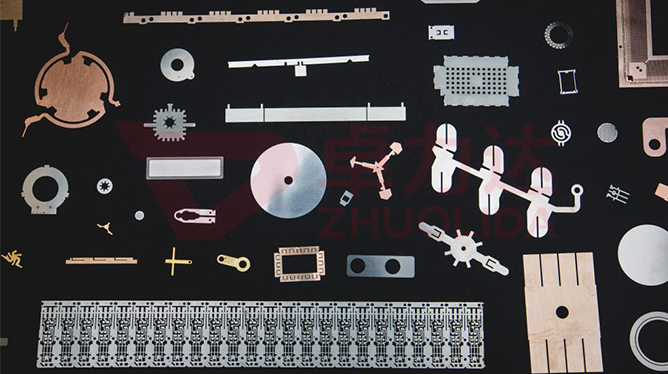

Slit sheet etching processing is a precise manufacturing technology, which is widely used in various fields, such as electronics, optics, precision machinery and so on. According to different application requirements, slit sheet etching processing can include the following types:

1. Metal slit sheet etching processing: metal slit sheet etching processing usually uses copper, nickel, chromium and other metal materials to manufacture metal slit sheets with high precision, good flatness and high finish. These slit sheets can be used in a variety of high-precision optical instruments, electronic equipment, medical equipment and other fields. In the metal slit sheet etching process, the etchant used is mostly acidic or alkaline solution, such as nitric acid, sulfuric acid, sodium hydroxide and so on.

2. Non-metallic slit piece etching processing: non-metallic slit piece etching processing is mainly used for plastics, resins, glass and other non-metallic materials slit piece manufacturing. This processing technology is commonly used in the manufacture of complex shapes and fine structure of the slit sheet, such as for optoelectronics, semiconductors, chemical reactors and other fields of precision parts. In the non-metallic slit slice etching process, the etchant used is mostly organic solvents or chemical reagents, such as acetone, phenol and so on.

3. Semiconductor slit sheet etching: semiconductor slit sheet etching is mainly used for fine processing and manufacturing of semiconductor materials, such as silicon, germanium, gallium arsenide, etc.. These semiconductor materials made of slit sheet with high electrical conductivity, high thermal conductivity and good chemical stability, commonly used in the manufacture of microelectronic devices, integrated circuits, optoelectronic devices. In the semiconductor slit slice etching process, the etchant used is mostly fluorine-containing solution or chlorine-containing gas, such as hydrofluoric acid, hydrogen chloride, etc..

4. Nano slit sheet etching processing: nano slit sheet etching processing is a cutting-edge technology, which can be manufactured on the nanometer scale with a specific shape and function of the slit sheet. These nano-slit slices have very high specific surface area and good electrical conductivity, which can be used to manufacture high-efficiency batteries, supercapacitors, fuel cells and other energy devices. In the nano-slit slice etching process, the etchant used is mostly a strong oxidizing solution or gas, such as silver nitrate solution, ozone gas and so on.

In short, there are various types of slit sheet etching processing, according to different materials and application requirements can choose the appropriate etching processing method. With the continuous development of science and technology, slit sheet etching processing technology will be more refined and diversified, providing more possibilities for innovation and development in various fields.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China