Etching is a manufacturing process in which a portion of a material's surface is removed through a chemical reaction for the purpose of creating or modifying a part. In the manufacturing of audio speaker grilles, there are several main reasons for choosing to etch audio speaker grilles. Firstly, audio speaker grille etching can produce very fine mesh holes which can have a very regular and consistent shape. Secondly, audio speaker grille etching can control the size and shape of the grille very well, so as to ensure that each speaker grille can fit perfectly with the speaker unit. In addition, audio speaker grille etching can also produce a variety of different patterns and styles on the grille, which helps to improve the overall appearance and attractiveness of the product.

In order to fully understand the application of etched audio speaker grille in the manufacturing of audio speaker grille etching process, below we will briefly introduce the process flow of audio speaker grille etching process. First is the preparation stage, this stage needs to prepare the appropriate materials and equipment, and check and maintain the equipment and materials. Next is the material stage, this stage needs to cut the raw material into blocks according to the required size. In the unloading process, equipment such as presses and cutting machines are used, which need to precisely control parameters such as pressure, speed and temperature to ensure the precision and quality of the unloading.

Next is the cleaning and pickling stage, which requires the cut raw materials to be cleaned and pickled to remove surface dirt, oxidized layer and impurities. Cleaning and pickling equipment mainly includes pickling tanks, water tanks, ovens and other equipment, which need to strictly control the temperature, time and quality of the washing liquid and other parameters to ensure that the best washing effect. After cleaning and pickling is the rolling and shearing stage, this stage needs to be cleaned raw materials for rolling and shearing treatment, in order to get the required shape and size. This stage requires the use of equipment such as rolling mills and shears, which need to accurately control parameters such as pressure, speed and shear angle to ensure that the required shape and dimensional accuracy is achieved.

The next stage is neutralization, phosphating and passivation, which are surface treatments for parts that have been shaped to increase corrosion resistance and surface hardness. These treatments require the use of appropriate chemical reagents and equipment, and need to strictly control the processing time, temperature and concentration and other parameters to ensure that the best processing results. Finally is the etching processing stage, this stage will have been through the surface treatment of parts for chemical corrosion treatment, in order to remove unwanted materials and form the desired shape and pattern. This stage requires the use of the appropriate chemical reagents and equipment, and need to accurately control the etching time, temperature and concentration and other parameters to ensure that the best etching effect.

After the etching of audio speaker grille stage there is a post-processing stage, this stage mainly includes cleaning, inspection and packaging and other links. In the cleaning process need to use to the sink, oven and other equipment, these equipment need to strictly control the temperature, time and the quality of the washing liquid and other parameters to ensure that the best washing effect. In the inspection process, the quality of the product needs to be checked to ensure that it meets the appropriate standards and requirements. Finally is the packaging link, this link needs to protect the product packaging, in order to avoid its damage or pollution in the transportation and storage process.

In addition to these links, the following quality control measures need to be paid attention to in the audio speaker grille etching process. The first is in the raw material preparation stage, you need to check and control the source and quality of the material to ensure that it meets the appropriate requirements and standards. Secondly, in the production process, the operational status and maintenance of equipment need to be checked and recorded to ensure the normal operation and service life of the equipment. It is also necessary to check and control each link in the production process to ensure that it meets the corresponding process requirements and quality standards. Finally, in the post-processing stage, the quality of the product needs to be checked and recorded, and its appearance, size and shape and other indicators are tested and recorded to ensure that they meet the appropriate standards and requirements.

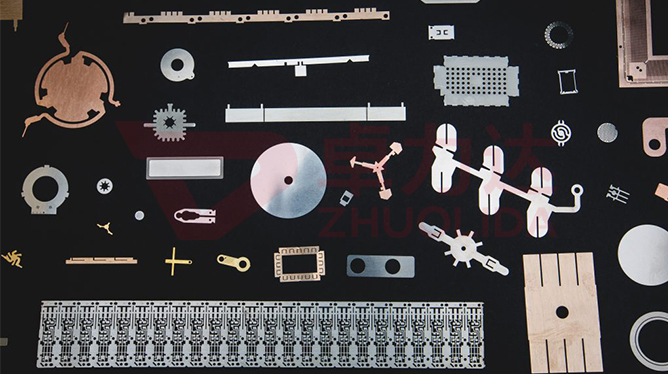

In conclusion, the use of etching process in the manufacture of audio speaker grille can achieve high precision, high speed and high efficiency manufacturing requirements.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China