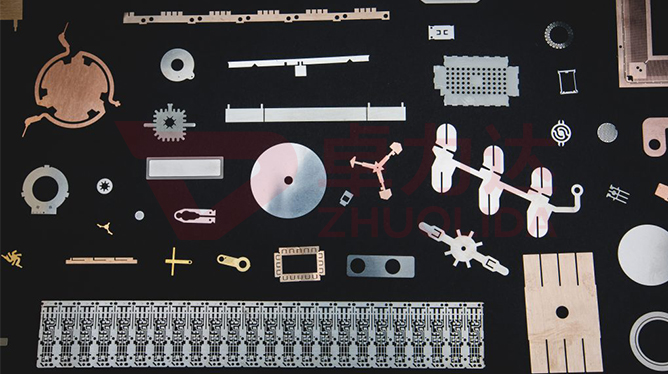

Precision gasket is a component used for sealing and cushioning, usually used in pipelines, valves, pumps and other equipment.During the manufacturing process, the accuracy and surface quality of precision gasket processing directly affects the performance and sealing effect of the equipment. Compared with stamping processing, etching processing has the following advantages:

1. Higher precision

Precision gasket precision requirements are very high, generally require thickness, contour and pore size error within a few microns. Precision gasket etching processing can ensure the thickness and pore size of the gasket by precisely controlling the chemical reaction and reaction time, and can also realize finer contour processing. In contrast, stamping is often limited by the hardness of the material, ductility and mold precision, it is difficult to achieve such high precision.

2. Applicable to a wider range of materials

Etching can be applied to a variety of materials, such as metals, ceramics, plastics, etc., while stamping is limited by the hardness and ductility of the material, can only be applied to materials with a certain degree of plasticity and toughness. This means that precision gasket etching processing can be made of a wider variety of materials to meet different application requirements.

3. Better surface quality

Etching can precisely control the surface quality by controlling the chemical reaction and reaction time. In the process of etching precision shims, different etching solutions and process parameters can be used to achieve better surface quality and uniformity. In contrast, the surface quality of stamping process is affected by factors such as mold wear, pressure and stretching, making it difficult to achieve high precision surface quality.

4. More flexible production

Precision gasket etching processing can produce precision gaskets of different specifications and designs by simply modifying the mask and etching solution. This makes production more flexible and can be adapted to the diverse needs of the market. Stamping processing, on the other hand, requires changing molds and adjusting stamping parameters to produce different shims, making it more suitable for mass production.

5. Higher production efficiency

Precision gasket etching processing can be completed in a short period of time a piece of gasket processing, and can be processed at the same time more than one gasket. In addition, precision gasket etching processing can also be automated equipment to achieve continuous production, thereby increasing production efficiency. In contrast, stamping processing requires a lot of time and manpower, and the molds are easy to wear and need to be replaced regularly, so the production efficiency is lower.

6. More environmentally friendly production methods

Etching process using chemical reagents generally have a certain degree of toxicity, need to be carried out in the sealed equipment, at the same time need to undergo a certain degree of environmental protection treatment. In contrast, stamping processing using molds and stamping equipment is prone to noise and vibration, but also easy to produce waste and waste, a certain impact on the environment.

7. Lower cost

Although the equipment and technology used in etching processing requires a certain amount of investment in capital and time to set up the production line, once established, its production costs are relatively low. In addition, etching processing can use fewer human resources, thus reducing labor costs. In contrast, stamping processing requires the use of a large number of molds and stamping equipment, and once the molds are worn out or damaged, repair or replacement costs are incurred.

In short, precision gaskets using etching processing has the advantages of higher precision, more flexible production, lower production costs and more environmentally friendly production methods compared to stamping processing. In the gasket sealing performance requirements are more and more high, more and more types of gaskets, the production scale is smaller and smaller in the modern industry, etching processing is a more competitive method of manufacturing precision gaskets.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China