Here’s a comprehensive overview of laser etching on stainless steel, covering its principles, techniques, benefits, applications, and considerations.

### Introduction to Laser Etching

Laser etching is a modern technique that utilizes high-powered lasers to engrave or etch designs onto various materials, including stainless steel. This method is celebrated for its precision,

versatility, and durability. Stainless steel, known for its strength and resistance to corrosion, is an ideal substrate for laser etching, making it popular in various industries and applications.

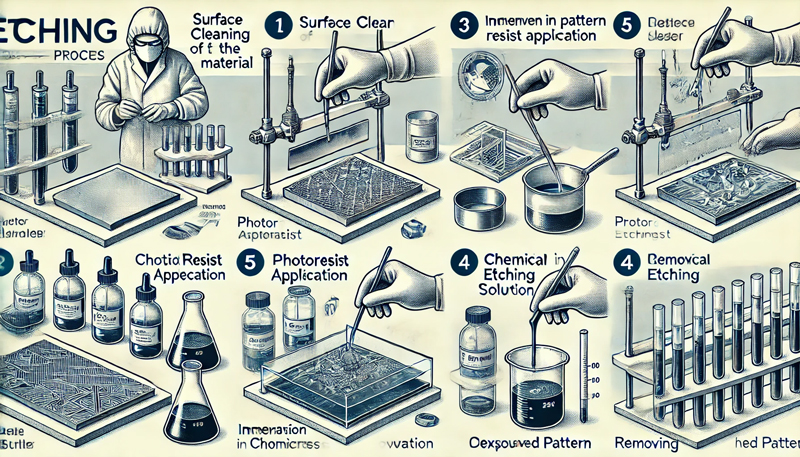

### The Laser etching process

#### 1. **Preparation**

Before the etching begins, proper preparation of the stainless steel surface is crucial. This step ensures that the final result is clean and clear:

- **Cleaning**: The surface is typically cleaned with solvents or abrasives to remove any oils, dust, or contaminants that could interfere with the laser’s effectiveness.

- **Masking**: In some cases, a masking tape or film is applied to protect areas of the steel that do not require etching.

#### 2. **Design Creation**

The design phase involves creating a digital representation of the desired outcome:

- **Graphic Design Software**: Designers use programs like Adobe Illustrator or CorelDRAW to create intricate designs or text. Vector formats (such as .SVG or .DXF) are preferred because

they maintain quality at any scale.

- **Consideration of Depth and Detail**: The complexity of the design and the desired depth of etching will influence the settings used during the actual etching process.

#### 3. **Laser Setup**

Once the design is finalized, the laser etching machine is prepared:

- **Choosing the Right Laser**: CO2 lasers are commonly used for etching stainless steel. They emit a wavelength that can effectively interact with the metal.

- **Settings Adjustment**: Key parameters such as power, speed, and frequency are adjusted based on the type of stainless steel, thickness, and intricacy of the design. Higher power and

slower speeds typically result in deeper etching.

#### 4. **Etching**

The actual etching process involves the following:

- **Laser Activation**: The laser is focused on the stainless steel surface. The energy from the laser beam vaporizes or melts the material, creating a permanent mark.

- **Layer Removal**: The laser etches away material in precise patterns, either creating shallow engravings for a subtle effect or deeper etchings for bold designs.

- **Monitoring**: Operators often monitor the process to ensure that the etching is proceeding correctly and to make any necessary adjustments in real time.

#### 5. **Finishing Touches**

After the etching is completed, additional steps may be taken to enhance the final product:

- **Cleaning**: Residual debris or oxidized material from the etching process is removed, typically using solvents or abrasive cleaning methods.

- **Inspection**: The final product is examined for quality assurance, ensuring that the design meets the required specifications.

### Benefits of Laser Etching on Stainless Steel

Laser etching offers several significant advantages:

#### 1. **Precision and Detail**

Laser etching can achieve intricate designs with high precision, allowing for fine details and complex patterns that might be difficult to replicate using traditional engraving methods.

#### 2. **Durability**

The etching is permanent and withstands wear and tear, making it suitable for items that will be exposed to harsh conditions or frequent handling. The marks are resistant to fading, corrosion,

and environmental factors.

#### 3. **Versatility**

Laser etching can be applied to various items made from stainless steel, including:

- Industrial parts and components

- Personalized gifts and awards

- Kitchenware and tools

- Jewelry and decorative pieces

#### 4. **Speed and Efficiency**

The laser etching process is relatively quick compared to other engraving methods, making it ideal for both small-scale projects and large production runs. It minimizes waste material, as it only removes

what is necessary.

### Applications of Laser Etching on Stainless Steel

Laser etching is employed across numerous industries for various applications:

#### 1. **Industrial Applications**

- **Labeling and Identification**: Companies often use laser etching for serial numbers, barcodes, and safety information on equipment and machinery.

- **Component Marking**: Parts and components can be etched with specifications or brand logos, aiding in quality control and traceability.

#### 2. **Personalized Products**

- **Gifts and Awards**: Customized engraving for trophies, plaques, or keepsakes is a popular use of laser etching.

- **Jewelry**: Laser etching allows for personalized messages or designs on rings, bracelets, and pendants.

#### 3. **Art and Design**

- **Decorative Items**: Artists and designers utilize laser etching to create unique pieces, such as wall art or sculptures, with intricate designs that catch the eye.

- **Architectural Elements**: Stainless steel panels and features in buildings can be etched with artistic patterns or branding elements.

### Considerations When Laser Etching

While laser etching has many advantages, there are some considerations to keep in mind:

#### 1. **Material Selection**

Different grades of stainless steel may react differently to laser etching. Some materials may require specific laser settings to achieve optimal results.

#### 2. **Heat Affected Zone (HAZ)**

The laser generates heat, which can cause a heat-affected zone around the etching. It’s important to manage this to prevent warping or discoloration of the metal.

#### 3. **Cost Factors**

While laser etching can be cost-effective, initial setup costs for high-quality machines and software can be significant. However, for large-scale production, these costs can be offset over time.

#### 4. **Skill Level**

Operating laser etching machines requires skill and experience. It’s important to ensure that operators are adequately trained to achieve the best results.

### Conclusion

Laser etching on stainless steel is a sophisticated and efficient technique that combines precision with versatility. Whether for industrial purposes, personalized products, or artistic

creations, this method offers a permanent and durable solution for marking and engraving. As technology continues to advance, the possibilities for laser etching will only expand,

making it an increasingly valuable tool across various industries. If you’re considering a project that involves laser etching, understanding the process and benefits can help you make

informed decisions and achieve outstanding results.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China