Laser etching stainless steel is a precise and efficient way to create designs, text, or images on the surface of the metal. Here are some key points to consider if you're thinking about laser etching stainless steel:

Fiber Lasers: Ideal for stainless steel due to their efficiency and ability to produce high-quality, detailed marks.

CO2 Lasers: Can also be used but are generally less effective on metals compared to fiber lasers.

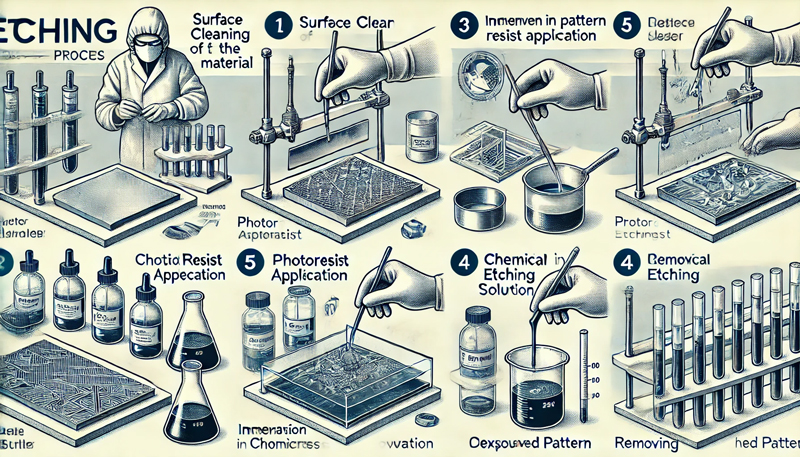

The stainless steel surface is cleaned to remove any contaminants.

The laser is programmed with the desired design.

The laser beam is directed onto the metal, which vaporizes a thin layer of the surface, creating the etch.

Durability: Laser etching creates a permanent mark that resists wear and corrosion.

Precision: Allows for intricate designs and fine details.

Speed: Fast processing times compared to traditional methods like engraving.

Personalization of items (e.g., jewelry, gifts).

Industrial marking (e.g., serial numbers, barcodes).

Artwork and decorative pieces.

Material Thickness: Thicker materials may require different settings.

Surface Finish: Different finishes (e.g., brushed, polished) can affect the final appearance of the etch.

Safety: Proper safety gear should be worn during the process, and the area should be well-ventilated.

If you're planning to get something etched, working with a professional service that specializes in laser etching is a good idea to ensure the best results!

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China