Etched stainless steel is created by using chemical, mechanical, or laser methods to produce designs, textures, or patterns on the surface of stainless steel. This process is popular in industries ranging from architecture to jewelry because of its durability, resistance to corrosion, and aesthetic appeal. Here’s an overview of how it works and its uses:

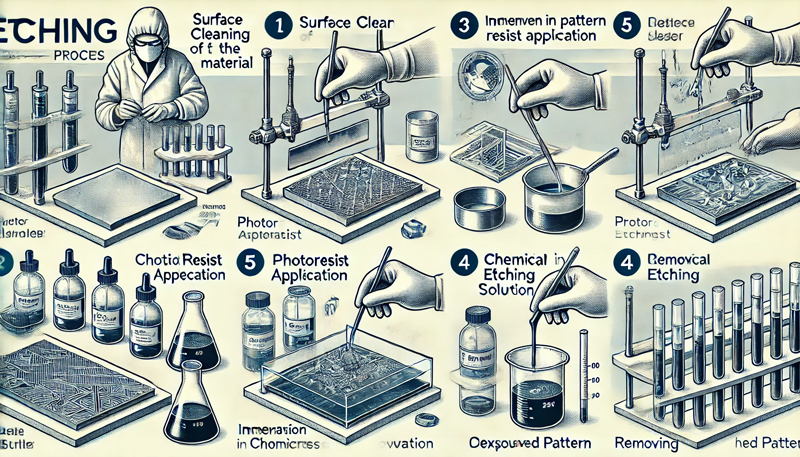

Preparation: The stainless steel surface is cleaned to remove oils, dust, and any contaminants.

Masking: A protective mask or resist is applied to areas that should remain untouched. This could be a design cutout or a stencil.

Chemical Etching: The exposed areas are treated with acid or a similar solution, which dissolves parts of the metal to create a design.

Mechanical Etching: Abrasive methods like sandblasting or brushing remove parts of the surface, resulting in a textured design.

Laser Etching: Laser beams vaporize specific parts of the steel surface, providing a precise and consistent etch.

Finishing: The etched piece is cleaned and sometimes polished, depending on the desired look.

Architectural Panels: Decorative building exteriors and interiors.

Signage: Used for durable and long-lasting signs.

Elevator Panels and Doors: Adds aesthetic appeal while withstanding heavy use.

Jewelry and Home Decor: Detailed designs with a modern metallic look.

Durability: Stainless steel is corrosion-resistant, making etched designs long-lasting.

Aesthetic Variety: Etching allows for custom designs, textures, and finishes.

Precision: Especially with laser etching, fine details and complex patterns can be achieved.

Let me know if you’re interested in specific applications or need guidance on a particular project with etched stainless steel!

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China