The development of new energy vehicles has led to a revolutionary leap in energy storage batteries, in which hydrogen fuel cells are also striding forward while lithium batteries are widely used. So what is a hydrogen fuel cell? Hydrogen fuel cells are made into energy storage batteries by using hydrogen chemical elements. The basic principle is to supply hydrogen and oxygen to the cathode and anode respectively through the reverse reaction of electrolyzed water. After hydrogen diffuses outward through the cathode and reacts with the dielectric, electrons are released to reach the anode through an external load. The main features are environmental protection, energy saving and high efficiency. The principle of hydrogen energy battery is that hydrogen reacts with oxygen to supply energy to the car, and finally forms water vapor to be discharged to the outside of the car, which has the characteristics of little pollution. Unlike traditional fuel engines, hydrogen energy battery will not release toxic and dust pollutants, and it has almost no pollution. The noise of hydrogen fuel cell cars is low during driving, and its power generation efficiency is as high as 50% or more, thus driving the kinetic energy of cars to be more efficient.

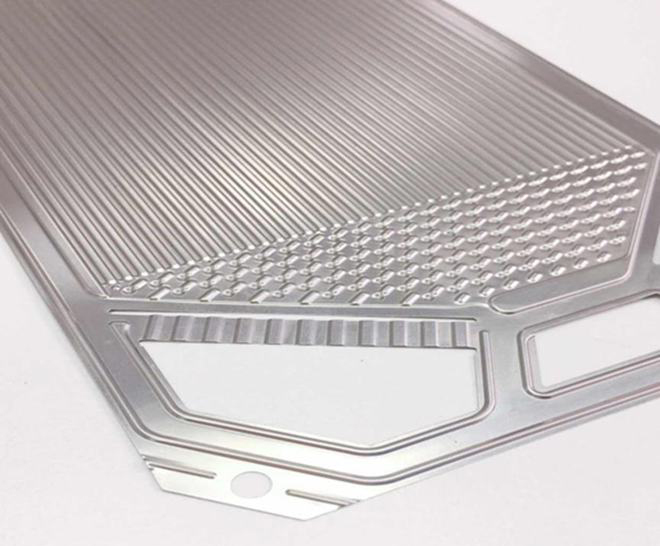

Bipolar plate has to be mentioned in hydrogen energy fuel cell, so what is bipolar plate? Bipolar plate plays the role of membrane electrode structure support, separating hydrogen and oxygen, collecting electrons, conducting heat, providing hydrogen and oxygen channels, discharging water generated by reaction and providing coolant channels in fuel cells. Bipolar plate can be divided into three types: graphite bipolar plate, metal bipolar plate and composite bipolar plate. Among them, metal bipolar plate is superior to graphite bipolar plate and composite bipolar plate in power, power density, weight, volume, mass production and cold start, and metal bipolar plate is mainly made of stainless steel, aluminum and titanium alloy.

With the continuous development of process equipment, etching technology is widely used in precision equipment processing. Etching hydrogen fuel bipolar plate can meet the requirement of manufacturing ultra-thin metal bipolar plate, and the minimum etching thickness can be 0.01MM and the maximum etching thickness is 2 mm. Therefore, hydrogen fuel bipolar plate can have an advantage in the ultimate design space through etching technology.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China