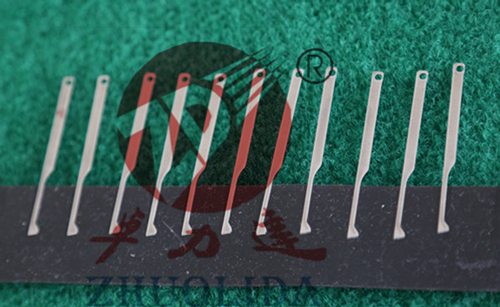

With the continuous development of modern surgery, surgical knives are more and more precise. In view of minimal trauma, surgical blades are constantly innovated. Surgical blades are used to cooperate with various scalpels for surgical operations or medical operations. They are basically used to cut and separate tissues. There are many types of blades, which can be divided into circular knives, curved knives, triangular knives, etc. According to their shapes, they can be divided into large blades, medium blades and small blades according to their sizes.

Traditional surgical blades are all made by precision machining, and the etching process has a high precision, the precision can reach ±0.01mm, and the small etching aperture is 0.1mm. The selected materials can be 304, 301, 316, 430, chromium, titanium, vanadium and other metals, and the thickness of the materials is 0.03mm, 0.06mm, 0.08mm, 0.15mm, 0. Surgical blade etching can make the product burr-free, high flatness, product deformation, and do not change the properties of the material. Because the etching process of surgical blade adopts low mold opening cost, the film of arbitrary shape and mesh can be changed, which can reduce the design and development cost.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China