When choosing a Stainless steel etching processor, the following factors are worth considering:

1. Quality: Preference is given to etching manufacturers with refined technology and equipment, as they can provide quality products as well as a perfect environmental protection system. In the evaluation process, it is necessary to know their environmental protection measures, such as whether they adopt the recycling of three-dimensional environmental protection system, in order to avoid environmental pollution problems as far as possible.

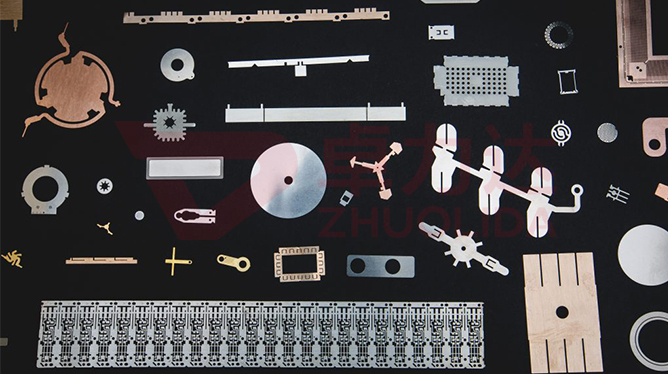

2. Production and scale: certain small-scale etching manufacturers may not be able to meet the demand, so you should choose a larger scale, higher processing precision manufacturers to ensure production efficiency and product quality.

3. Price: the price needs to be within a reasonable range, at the same time, the manufacturer should have fine workmanship and reasonable price, in order to provide timely service and improve the competitiveness of enterprises.

4. Service: preferred manufacturers can provide quality services, such as SOP standardized process system, which can help control the differences in the process and the realization of the process, to prevent quality problems in the processing.

5. Technological innovation: for example, Jolytek etching program, after chemical etching, simplifying the traditional etching preparation work, can be completed in just one step, greatly improving the efficiency and no environmental pollution.

After considering the above factors, you can choose the right stainless steel etching processor according to your actual needs.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China