As a semiconductor material, silicon nitride (SiC) has very high thermal conductivity, strong electron saturation rate and radiation resistance, and obvious advantages such as easy heat dissipation, small volume, low energy consumption and high power.

The new energy vehicle can effectively accelerate the performance and output the maximum power of the power system through silicon nitride (SiC), and improve the acceleration; In the field of new energy vehicles, the cruising range and charging time are important. In order to improve the voltage, reduce the power consumption loss, improve the efficiency and increase the cruising range, silicon nitride (SiC) devices can improve the on/off dimensions and reduce the loss. Silicon nitride (SiC) material can realize high-frequency switching, reduce filters and passive devices, thus reducing battery capacity and contributing to vehicle lightweight.

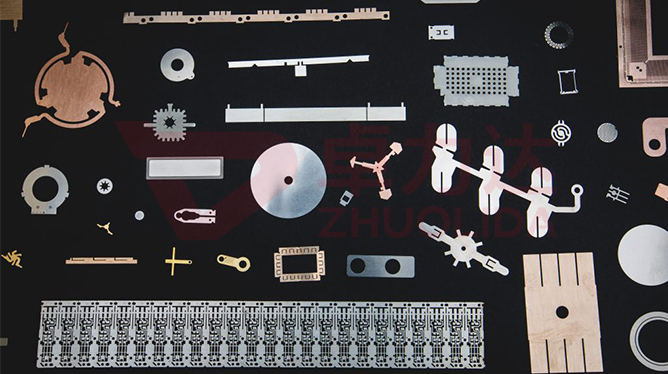

Silicon nitride ceramic liner, also known as ceramic circuit board, is made of ceramic substrate by copper cladding technology, and then made into ceramic circuit board by laser drilling, pattern etching and other processes. At present, it has gradually become the best material for SiC chip packaging with excellent thermal conductivity and bending resistance of automobile enterprises.

The silicon nitride ceramic copper substrate can ensure the product performance advantage, fine and smooth surface and no burr through etching. Through the etching process, the welding layer of ceramic copper substrate can be etched. Etched ceramic copper substrate is more reliable in service at high temperature, which is gradually becoming the first choice favored by steam enterprises.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China