As a material with high corrosion resistance and excellent mechanical properties, titanium is widely used in various industrial and scientific applications. Titanium also plays an important role in the field of hydrogen fuel cells, being used as a bipolar plate material for fuel cell stacks. In this paper, we will discuss the advantages of etching and processing of titanium bipolar plates and why titanium was chosen as a material for hydrogen fuel cell stacks.

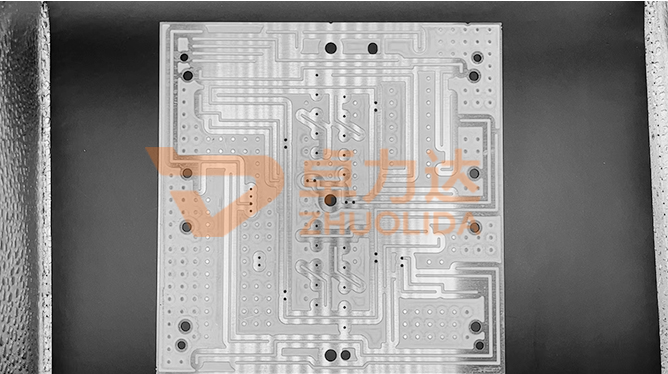

First, let's talk about the advantages of titanium bipolar plate etching processing. Etching is a process of fabricating and machining sheet metal in which unwanted parts are removed by corrosion through a chemical reaction, leaving the desired shape and structure. In the manufacturing process of titanium bipolar plates, titanium bipolar etching processing has the following advantages:

1. High precision: Through the etching process, complex three-dimensional shapes and precise dimensions can be accurately manufactured, thus realizing higher assembly precision and lower internal resistance.

2. High efficiency: Etching process can realize high efficiency on large area of metal surface, which improves the production efficiency and reduces the production cost.

3. High reliability: During the etching process, the material is removed uniformly, the edges are clear and the surface quality is high, which makes the quality of titanium bipolar plates more reliable.

4. Versatility: Etching processing can be adapted to a variety of titanium alloys, coatings and composites, thus meeting different application requirements.

Next, let's see why titanium is chosen as the material for hydrogen fuel cell stacks. Titanium bipolar plates have the following unique advantages, making it an ideal material for hydrogen fuel cell stacks:

1. Corrosion resistance: The chemical reaction rates of hydrogen and oxygen on titanium surfaces are much slower than on most other metal surfaces. Therefore, titanium has excellent corrosion resistance and oxidation resistance in hydrogen environment, which can effectively prevent the occurrence of hydrogen embrittlement.

2. Hydrogen permeability: Titanium has high hydrogen permeability, which can realize hydrogen adsorption and desorption at lower temperature and pressure, thus improving the efficiency and performance of hydrogen fuel cell.

3. Mechanical strength and ductility: titanium is a metal material with excellent mechanical strength and ductility. This enables titanium to withstand high pressure and high temperature working environment while maintaining stable performance when used as bipolar plate material in fuel cell stacks.

4. Coefficient of Thermal Expansion: Titanium has a low coefficient of thermal expansion, which enables it to better adapt to the deformation caused by temperature changes during fuel cell operation, thus reducing the risk of damage or performance degradation caused by thermal stress.

5. Biocompatibility: Titanium is a biocompatible material that is widely used in the medical field. Therefore, choosing titanium as a material for hydrogen fuel cell stacks ensures good biocompatibility within the human body or in the environment, reducing potential health risks.

In summary, titanium bipolar plate etching processing has the advantages of high precision, high efficiency, high reliability and versatility. Titanium is chosen as the material for hydrogen fuel cell stacks because of its good corrosion resistance, hydrogen permeability, mechanical strength and ductility, coefficient of thermal expansion, and biocompatibility. These advantages make titanium an ideal fuel cell stack material and provide strong support for improving the performance and reliability of hydrogen fuel cells.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China