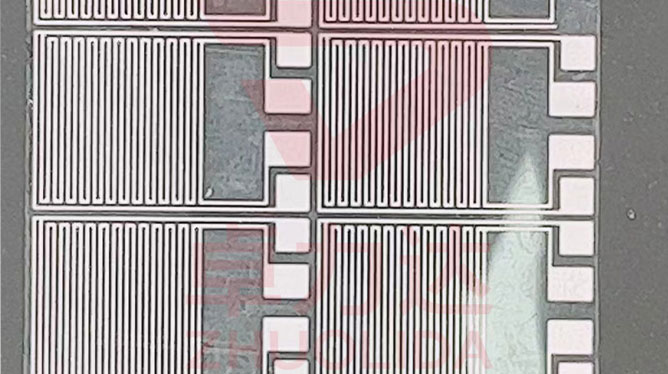

LED lamp QFN bracket etching and EMC bracket etching both use etching processing for the following main reasons:

1. High precision: lead bracket etching processing can very accurately control the shape and size of the part, which is very important for QFN bracket etching and EMC bracket etching. The precision of the lifting bracket will directly affect the assembly and performance of the LED light.

2. Good surface quality: leadframe etching process can obtain very smooth surface quality, which is very important to improve the reliability and life of LED lights. In addition, good surface quality can also reduce the friction between the bracket and the electronic components and improve the assembly efficiency.

3. Wide range of material applicability: leadframe etching processing can be applied to a variety of metal materials, such as copper, nickel, chromium, etc., which makes it an ideal material choice for manufacturing QFN bracket etching and EMC bracket etching. These metal materials have good electrical and thermal conductivity and can meet the performance requirements of LED lights.

4. High flexibility: leadframe etching processing can easily change the shape and size of the part by changing the mask or using different etchant, which makes it possible to quickly adapt to different design requirements in production.

5. Low manufacturing cost: Compared with other processing methods, the manufacturing cost of leadframe etching is relatively low. This is mainly due to its high productivity, which allows it to process multiple parts simultaneously in a single process, thus reducing the unit cost.

6. Environmentally friendly: The chemicals used in the process of leadframe etching processing can be recycled and do not produce a large amount of waste, which makes it an environmentally friendly manufacturing method.

To summarize, etching processing has significant advantages in the production of LED lamp QFN bracket etching and EMC bracket etching. Its high precision, good surface quality, wide range of material applicability, high flexibility, low manufacturing cost and environmental friendliness make it the preferred method for manufacturing these parts.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China