Etching of Stainless Steel 304 is an advanced metal processing technology that has the advantage of being able to finish the surface of the metal to a very smooth finish, as well as creating metal products of various shapes and structures. This processing technology is widely used in aviation, aerospace, medical, electronics, automotive and other fields. This article will focus on the characteristics and applications of stainless steel 304 etching processing.

First, the characteristics of stainless steel 304

Stainless steel 304 is a stainless steel material with excellent corrosion resistance and processing performance, its composition and properties are as follows:

Composition: Stainless steel 304 is mainly composed of iron, chromium, nickel and other elements, of which the content of chromium is high, reaching more than 18%, and the content of nickel is also above 8%.

Properties: Stainless steel 304 has excellent corrosion resistance and can maintain stable performance in a variety of corrosive media. In addition, it also has good processing performance and welding performance, can carry out a variety of cold and hot processing and welding operations.

Second, the characteristics of the etching process

Etching processing is a combination of chemical reaction and physical impact method, the metal surface treatment is very smooth technology. Specifically, it has the following characteristics:

Good surface quality: etching can obtain a very smooth metal surface, the roughness can reach the nanometer level, while also controlling the surface hardness, wear resistance and corrosion resistance.

High processing precision: the precision of etching processing is very high, can reach the micron level, so it can meet the requirements of high-precision processing.

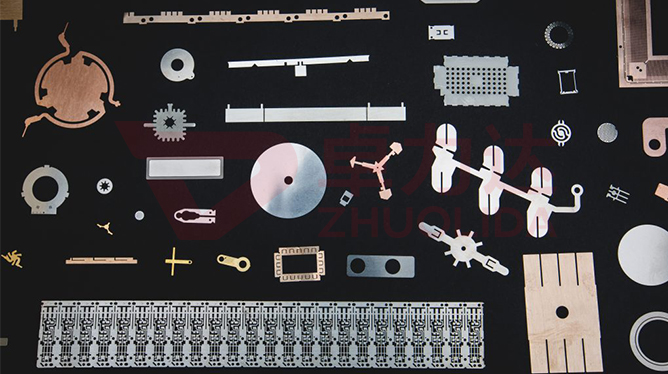

Wide range of application: etching can be applied to metal products of various shapes and sizes, from simple two-dimensional graphics to complex three-dimensional structures can be processed.

Environmental protection and energy saving: the etching process does not use chemical reagents and harmful substances, so it will not produce environmental pollution and health hazards and other issues.

Third, the application of stainless steel 304 etching process

Due to the excellent corrosion resistance and processing performance of stainless steel 304, it is widely used in a variety of fields, in which the application of etching processing technology is also very extensive. The following are a few typical application examples:

Aerospace field: Stainless steel 304 is widely used in the aerospace field to manufacture aircraft parts, satellite mounts and other metal products. In the manufacturing process of these products, etching processing technology is used to treat the metal surface, improve its corrosion resistance and appearance quality.

Medical field: Stainless steel 304 is widely used in the medical field to manufacture medical devices and surgical instruments. In the manufacturing process of these products, etching processing technology is used to treat the metal surface, improve its corrosion resistance and hygiene performance.

Electronic field: Stainless steel 304 is widely used in the electronic field to manufacture electronic components and circuit boards and other products. In the manufacturing process of these products, etching processing technology is used to deal with the metal surface, improve its electrical conductivity and corrosion resistance.

Automotive field: Stainless steel 304 is widely used in the automotive field for the manufacture of automotive parts and body structures and other products. In the manufacturing process of these products, etching technology is used to treat the metal surface, improve its corrosion resistance and appearance quality.

In short, the etching processing of stainless steel 304 is an advanced metal processing technology, the advantage of which lies in its ability to treat the metal surface very smooth, and at the same time, it can also produce a variety of shapes and structures of metal products. This processing technology is widely used in aviation, aerospace, medical, electronics, automotive and other fields, making an important contribution to the development of these fields.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China