Stainless steel etching manufacturer, is the etching processing manufacturer on stainless steel material. Stainless steel is a metal material with high corrosion resistance and aesthetics, which is widely used in construction, decoration, industry and other fields. Etching processing, on the other hand, is the use of chemical or physical methods on the surface of the material to obtain the desired pattern, text, graphics, etc..

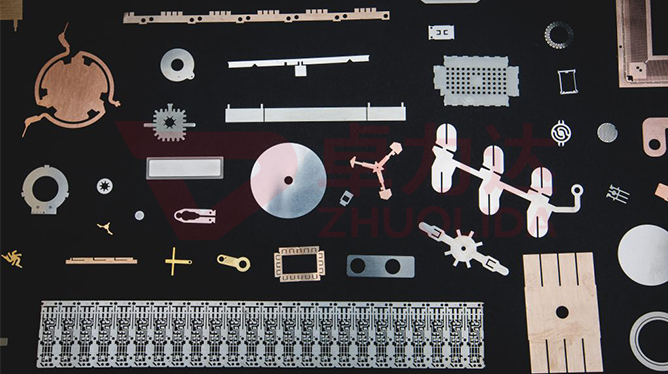

Stainless steel etching manufacturers have a wide range of applications in the industry. For example, in the field of construction, stainless steel etching manufacturers can produce a variety of patterns and text for building decoration and labeling; in the industrial field, stainless steel etching manufacturers can produce a variety of precision parts and tools for machinery, electronics, aviation and other fields.

The production process of stainless steel etching factory mainly includes the following steps:

1. Material preparation: stainless steel etching plant first need to prepare the required stainless steel material, and clean and dry it.

2. Etching process: according to customer demand, the use of chemical or physical methods in the stainless steel material for etching process.

3. Cleaning and drying: after the etching process is completed, the stainless steel etching plant needs to clean and dry the processed material.

4. Quality inspection: Stainless steel etching plant needs to carry out quality inspection on the processed products to ensure that it meets the needs of customers.

5. Packaging and shipment: After the quality inspection of qualified products, stainless steel etching factory will be packaged and shipped.

Stainless steel etching manufacturers need to pay attention to the following points in the production process:

1. Process control: stainless steel etching processing requires strict control of process parameters, such as temperature, time, concentration, etc., to ensure processing quality and efficiency.

2. Equipment selection: according to different needs, stainless steel etching manufacturers need to choose the right equipment to ensure processing efficiency and precision.

3. Material selection: the choice of stainless steel material will also affect the quality and efficiency of the etching process, so we need to choose the right stainless steel material according to different needs.

4. Environmental protection: attention needs to be paid to environmental protection in the production process, such as waste gas, waste water treatment and recycling of waste.

The development trend of stainless steel etching manufacturers mainly has the following aspects:

1. Technological innovation: with the continuous development of science and technology, the technology of stainless steel etching processing is also constantly updated and improved. In the future, stainless steel etching manufacturers need to constantly carry out technological innovation to improve processing efficiency and precision.

2. Diversification: With the changes in market demand, stainless steel etching manufacturers need to develop more products and services to meet the needs of different customers.

3. Green environmental protection: with the increasing awareness of environmental protection, stainless steel etching manufacturers need to pay more attention to environmental protection and promote the concept of green production.

4. International cooperation: With the continuous development of globalization, stainless steel etching manufacturers need to strengthen cooperation and communication with international enterprises to expand the international market and introduce advanced technology.

In short, stainless steel etching manufacturers is an important part of the metal processing field, and its development status is closely related to the development of the whole industry. In the future, stainless steel etching manufacturers need to continuously carry out technological innovation, diversified development, green environmental protection and international cooperation to adapt to market demand and industry trends.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China