Precision dust and fire protection mesh is a widely used protective product in industry and commerce, whose main function is to prevent dust and ignition sources from entering into equipment or systems, thus ensuring safe and stable operation. Due to its special use and performance requirements, the material selection of precision dust and fire prevention mesh has some special requirements.

First, the material must have high corrosion resistance. Precision dustproof and fireproof mesh usually needs to be exposed to various environments, such as high temperature, low temperature, humidity, corrosive gases and so on. Therefore, the material must have excellent corrosion resistance and be able to maintain stable and reliable performance in various environments. Stainless steel is a commonly used material because it contains elements such as chromium and nickel, which are effective in resisting oxidation and corrosion.

Second, the material must have high thermal conductivity. Precision dust and fire protection mesh is usually subjected to high temperatures and heat, so the material must have high thermal conductivity and be able to dissipate heat quickly to prevent heat buildup and excessive temperatures. Metallic materials such as copper and aluminum have good thermal conductivity and can meet this requirement.

Third, the material must have high strength and stiffness. Precision dustproof and fireproof mesh needs to withstand a variety of external forces and pressures, so the material must have high strength and stiffness, which can ensure the stability and durability of the mesh. Stainless steel, copper and aluminum and other metal materials have high strength and stiffness, can meet this requirement.

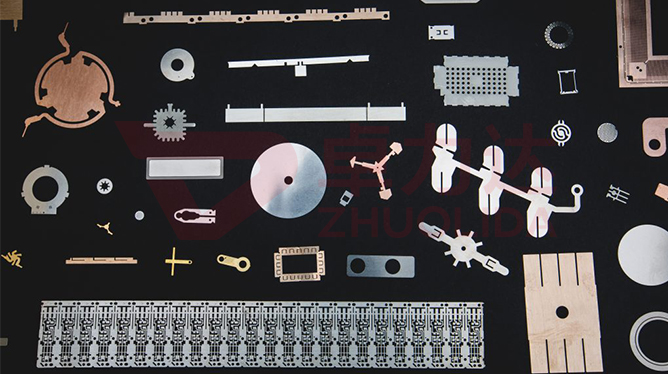

Fourth, the material must have good processing performance. Precision dust and fire mesh mesh shape and size requirements are strict, so the material must have good processing performance, can be stamping, cutting, bending and other processing procedures to create a mesh to meet the requirements. Stainless steel, copper and aluminum and other metal materials have good processing performance, can meet this requirement.

Fifth, the material must be aesthetically pleasing. Precision dust and fire prevention mesh is often exposed to the line of sight, so the material must be aesthetically pleasing to meet the visual requirements. Stainless steel is a material with elegant appearance, can be polished or plastic spraying and other surface treatment methods to improve its aesthetics.

To summarize, the material selection of precision dustproof and fireproof mesh needs to meet the requirements of high corrosion resistance, high thermal conductivity, high strength and stiffness, good processing performance and aesthetics. When selecting materials, comprehensive consideration needs to be made according to the purpose of the mesh and the use environment to ensure the manufacture of high-quality precision dustproof and fireproof mesh products.

In addition to the requirements mentioned above, the following factors need to be considered in the selection of materials for precision dustproof and fireproof mesh:

1. Cost of materials: the cost of different materials varies greatly, taking into account the manufacturing and production costs, need to meet the performance requirements under the premise of choosing a reasonable cost of materials.

2. Environmental protection of materials: modern industry is increasingly focusing on environmental protection and sustainable development, so it is also very important to choose environmentally friendly materials. For example, you can choose recyclable materials or low carbon emission materials.

3. Market supply of materials: the supply of different materials varies, and choosing materials with sufficient market supply and easy procurement can reduce production and supply chain risks.

4. Material compatibility: Precision dust and fire protection mesh is often connected to or in contact with other equipment or systems, so material compatibility needs to be considered. For example, compatibility with certain chemicals or lubricants.

In summary, the selection of materials for precision dustproof and fireproof mesh needs to consider a variety of factors, including corrosion resistance, thermal conductivity, strength and stiffness, processing performance, aesthetics, cost, environmental protection, market availability and compatibility. These factors need to be taken into account when selecting materials to ensure that high quality, high performance precision dust and fire prevention mesh products are manufactured to meet market demand.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China