Process: Apply a resist (like wax or an acid-resistant film) to areas you want to protect, then use a chemical acid (like ferric chloride) to etch the exposed areas.

Applications: This method is popular for intricate designs, logos, or labels on stainless steel.

Safety: Use gloves, goggles, and work in a well-ventilated area, as some chemicals can be dangerous.

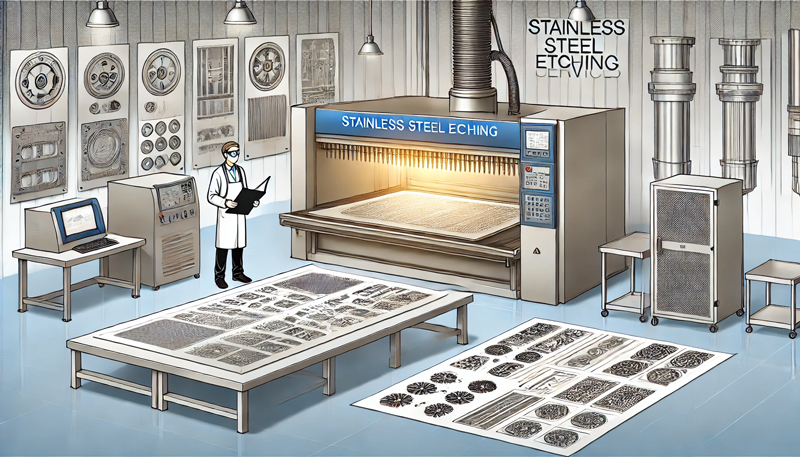

Process: A laser removes a small amount of material from the stainless steel, creating a smooth, detailed mark.

Applications: Laser etching is commonly used for high-detail images, serial numbers, or barcodes and is faster and precise.

Equipment: This requires a laser etching machine suitable for metals.

Process: Use a stencil with an electrolyte solution and an electric current to mark the stainless steel.

Applications: Widely used for parts marking or branding on tools and metal objects, as it is a clean and straightforward method.

Equipment: You’ll need an electrolyte solution, stencil, and a low-voltage power supply.

Process: Use a rotary tool or engraving machine to physically remove material from the surface of the stainless steel.

Applications: This is better for deeper or more textured designs, though it may lack the fine detail of chemical or laser etching.

Each method offers different levels of detail, durability, and surface finish, so you can choose based on the look and permanence you're aiming for.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China