metal etching processing is an important manufacturing technology, widely used in electronics, aviation, medical, decoration and other fields. In this article, we will introduce the basic principles of metal etching processing, types of etchant, steps of etching process, advantages of etching processing and selection of metal etching processing manufacturers.

First, the basic principle of metal etching processing

Metal etching processing is a kind of chemical reaction will be utilized to process the metal surface into the desired shape and pattern of the process. During the etching process, the metal surface is dissolved, forming grooves or bumps to achieve the desired shape and pattern. The rate of etching depends on the type of metal material, the surface finish and the type of etchant.

II. Types of etchant

Depending on the metal material and processing needs, the type of etchant is different. Common etchant includes acid etchant, alkaline etchant, electrochemical etchant and so on. Acidic etchant is suitable for etching of metal materials such as copper, aluminum, nickel, etc. Alkaline etchant is suitable for etching of metal materials such as iron, chromium, zinc, etc. Electrochemical etchant is suitable for high-precision and high-efficiency etching.

Third, the steps of etching process

1. Prepare the metal surface: clean the metal surface, remove grease, oxides and other impurities to improve etching speed and accuracy.

2. Coat the protective layer: in the area that does not need to be etched coated with a protective layer to avoid these areas are dissolved.

3. Apply etchant: Apply etchant to the metal surface so that it penetrates into the area to be processed.

4. Etching: Place the metal into the etching machine for etching, adjusting the etching time and temperature as needed.

5. Cleaning and drying: Clean the metal surface, remove the residual etchant and protective layer, and dry it.

6. Inspection and trimming: check whether the shape and pattern after processing meet the requirements, if necessary, can be trimmed.

Fourth, the advantages of metal etching processing

1. High precision: metal etching processing can obtain high-precision shapes and patterns, suitable for high-precision manufacturing needs.

2. Wide range of application: metal etching processing is applicable to a variety of metal materials, such as copper, aluminum, iron, chrome, etc., applicable to a variety of manufacturing areas.

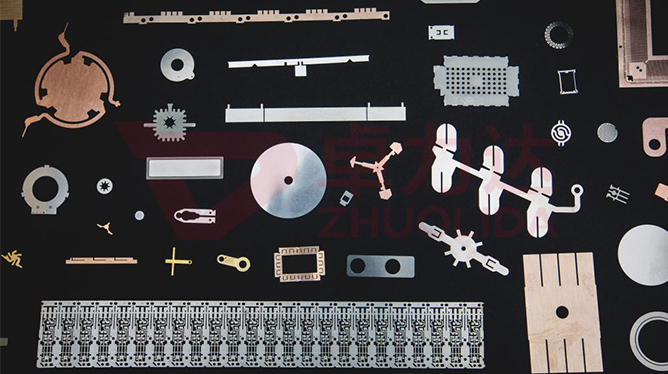

3. Complex shapes can be processed: metal etching processing can process complex shapes and patterns, such as circuit boards, micro-mechanical components and so on.

4. Environmental protection: the chemical reagents used in the process of metal etching processing can be recycled, reducing the impact on the environment.

Fifth, the choice of metal etching processing manufacturer

In the choice of metal etching processing manufacturers, need to consider the following aspects:

1. Professional ability: choose manufacturers with rich experience and professional ability to provide high-quality etching processing services.

2. Equipment and technology: consider the equipment and technology level of the manufacturer, advanced equipment and technology can improve processing efficiency and precision.

3. Quality management: choose the manufacturer with perfect quality management system, which can guarantee the processing quality and delivery time.

4. Price and after-sales service: consider the price and after-sales service of the manufacturer, choose the manufacturer with reasonable price and thoughtful service.

In short, metal etching processing is an important manufacturing technology that can meet a variety of manufacturing needs. When choosing a manufacturer, you need to consider the manufacturer's professional ability, equipment and technology level, quality management and price and after-sales service to ensure that you get high-quality processing services.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China