Stainless steel etching is a precision technique for making metal products, and the process can vary depending on the application and product requirements. The following is an overview of a common stainless steel etching process, but please note that this does not apply in all cases:

一、 Design and preparation

1. Drawing design: According to the customer's requirements or specific applications, start designing and drawing stainless steel products. Considering the size, shape, structure, surface treatment and precision requirements of the products, to ensure that the drawings are as detailed and accurate as possible.

2. Material selection: According to the application and working environment of the products, select the appropriate type of stainless steel. Common types of stainless steel include 304, 316, 316L and so on.

3. Tools and equipment preparation: prepare the tools and equipment needed for etching process, such as cutting machine, grinding machine, sand blasting machine, etching agent and so on.

二、 material cutting and molding

1. Cutting: According to the drawing design, use the cutting machine to cut the stainless steel plate into appropriate size and shape.

2. Forming: Use molds or machining equipment to shape the stainless steel material into its final shape.

三、 surface treatment

1. Grinding: Use sandpaper or sanding machine to clean and smooth the surface of stainless steel, remove burrs and rough parts.

2. Cleaning: Use solvent or detergent to clean the stainless steel surface to remove grease, dirt and dust.

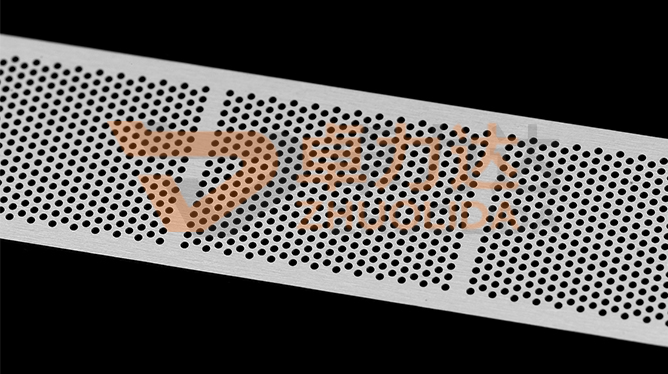

3. Etching: According to the design drawings, use the etchant to etch the desired pattern or text on the stainless steel surface. Etchant is a chemical solution that can produce a chemical reaction on the surface of stainless steel, forming grooves or lines.

四、 post-processing

1. Cleaning and drying: Rinse the stainless steel surface with water to remove residual etchant and impurities, and then dry.

2. Inspection and correction: check the shape, size and etching effect of the product, if necessary, repair or rework.

3. Painting or protection: In order to prevent the products from rusting or keep their surface gloss, a protective film or coating can be applied. Select the appropriate coating and paint according to the product requirements.

五、 Quality inspection and delivery

1. Quality Inspection: Conduct quality inspection on the products to ensure that they meet the design requirements and quality standards specified by the customer. Inspection items may include size inspection, surface treatment inspection, etching effect inspection, etc.

2. Packaging and delivery: Pack the products according to the customer's requirements to ensure that they are not damaged during transportation. Deliver the products to customers or transportation companies to complete the entire stainless steel etching process.

It should be noted that the specific stainless steel etching process may vary according to different applications, product materials and working environment. In practice, additional steps or equipment may be required to meet specific needs. Therefore, when performing stainless steel etching processing, a detailed plan and operation steps need to be developed according to the specific situation.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China