Stainless steel microporous processing, do you understand? Today we will unveil this mystery to see how powerful this technology is!

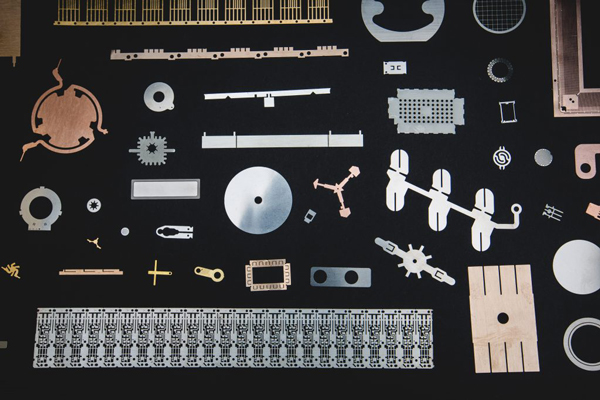

In industrial production, the application of microporous processing technology is becoming more and more widespread, and stainless steel microporous processing is more popular. Through high-precision processing technology, stainless steel can be made into tiny holes, used in filters, instrumentation and other fields. The importance of this technology lies not only in its ability to improve product quality and performance, but also in its ability to bring higher economic benefits.

In the field of stainless steel microporous processing, professional technology and equipment are essential. Select stainless steel microporous processing can be used in the etching process, etching thickness between 0.01MM-2MM, etching precision can reach ± 0.01MM, the use of chemical corrosion processing, the main component of ferric chloride mixed with water.

Stainless steel microporous processing, is a technology that people love and hate, due to the high pollution, so it is necessary to establish a fully automated recycling environmental protection system, although it requires high-precision equipment and technology, but it can bring us higher economic benefits and better product quality. How do you think this technology will develop in the future?

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China