Stainless steel etching process is a technology that utilizes chemical or physical methods to create various patterns or words on the surface of stainless steel. This process combines artistry and technology, so that stainless steel products not only have strong and durable characteristics, but also present a unique visual effect. The following will be a detailed introduction to the stainless steel etching process.

First, the basic principle of stainless steel etching process

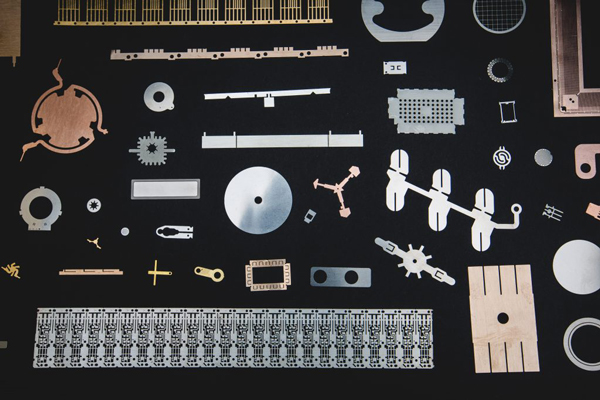

The basic principle of stainless steel etching process is to form a layer of resist film on the surface of stainless steel through a specific method, and then through the corrosion effect, so that the part of the metal that is not covered by the resist film is etched away, thus leaving the desired pattern or text. According to the resist film material used and the different corrosion methods, the etching process can be divided into a variety of types, such as chemical etching, electrolytic etching, laser etching and so on.

Second, the main steps of stainless steel etching process

Surface treatment: before starting the etching, the stainless steel surface needs to be cleaned and pre-treated to ensure that the resist film can be uniformly attached to the metal surface. This usually includes the removal of oil, oxides and other impurities, as well as the necessary polishing or abrasive treatment.

Applying a Resist Film: Next, a resist film is applied to the stainless steel surface. This film can be screen printed, photographed or inkjet printed to form the desired pattern or text. The material of the resist film is usually corrosion-resistant inks or coatings, which are resistant to corrosive liquids.

Etching treatment: After the resist film has dried, the stainless steel is placed in an etching solution for etching treatment. The choice of etching solution depends on the resist material used and the desired etching effect. During the etching process, the part of the metal not covered by the resist film will be etched away, while the part protected by the resist film is retained.

Cleaning and drying: After etching is complete, the stainless steel needs to be removed from the etching solution and thoroughly cleaned and dried. This helps to remove the residual etching solution and resist film, making the etching pattern clearer.

Post-treatment: Finally, the etched stainless steel is post-treated as needed, such as polishing, coloring or encapsulation. These treatments can enhance the visual effect of the etching effect and improve the added value of the product.

Third, the application of stainless steel etching process

Stainless steel etching process is widely used in many fields, such as architectural decoration, art production, signage production, etc.. In the field of architectural decoration, stainless steel etching can be used to produce a variety of artistic sense of wall decoration, door and window decoration and furniture components. In the field of art production, stainless steel etching can create unique sculptures, murals and decorations. In the field of signage production, stainless steel etching can be used to produce recognizable trademarks, logos and signs.

Fourth, the development prospects of stainless steel etching process

With the progress of science and technology and people's pursuit of beauty continues to improve, the application of stainless steel etching process is more and more broad prospects. In the future, the process will continue to innovate in materials, equipment and technology to meet the needs of different areas. At the same time, with the enhancement of environmental awareness, how to reduce environmental pollution in the etching process and improve energy efficiency will also become an important direction for the development of the process.

In summary, the stainless steel etching process is a unique process that integrates artistry and technology. By mastering its basic principles and steps, combined with the needs of practical applications and development trends, we can better utilize the potential of this process to create more works and products with artistic value and practical value.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China