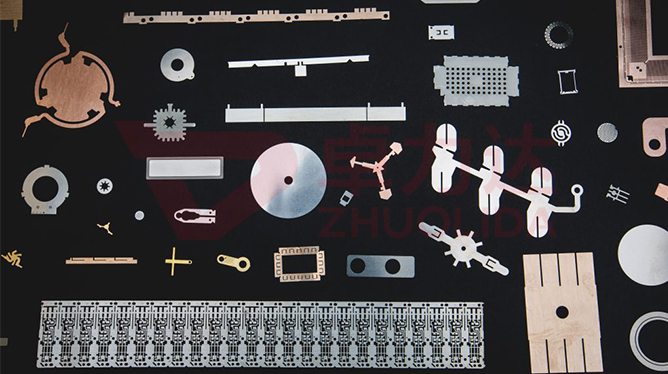

Incremental metal pallets are widely used in automation equipment, industrial robotics, aerospace, automotive manufacturing and other fields due to their high precision, high reliability, and strong anti-jamming ability. Choosing the etching process to produce incremental metal pallets has many advantages, including increased precision, improved quality, reduced cost, environmental protection and energy saving. The following is a detailed analysis of the advantages of choosing etching processing for incremental metal pallets:

1. Improve precision: the precision of incremental metal coding disk etching processing is critical to the operation of the entire system. The metal code plate etching processing plant can achieve high precision code plate production. By accurately controlling the etching depth and etching shape, it can ensure that the etching accuracy of the code disk is ideal. In addition, etching processing can also eliminate the traditional machining process may occur during the tool wear, vibration and other factors that affect the accuracy.

2. Enhance the quality: metal yard plate etching processing plant can significantly improve the quality of incremental metal yard plate. The etching process can achieve fine engraved lines on the very thin code disc material, making the code disc engraved lines more clear and durable. At the same time, the metal etching process can also effectively reduce the roughness of the surface of the code disc, improve the friction resistance and wear resistance of the code disc. These advantages can effectively improve the service life and performance of the incremental metal disk.

3. Reduce costs: Compared with traditional machining, metal disk etching has obvious cost advantages. The equipment of the metal code disk etching processing plant is relatively simple, and the investment cost is low. In addition, the etchant and gas used in the metal etching process can be recycled, reducing production costs. At the same time, etching processing can realize mass production, improve production efficiency, thus reducing the unit product cost.

4. Strong adaptability: etching process has a strong adaptability, can process a variety of different materials, shapes and sizes of incremental metal code disk. In addition, etching processing can also realize a variety of engraved line shape and structure of the code plate production, to meet the needs of different application scenarios.

5. Environmental protection and energy saving: the etchant and gas used in the etching process of the metal disk can be recycled and disposed of, reducing the impact on the environment. At the same time, the equipment of metal disc etching processing plant usually has high energy utilization rate, which helps to save energy.

6. High efficiency: the metal code plate etching process can realize continuous and automated production, which improves the production efficiency. In addition, there is no need to change tools during the etching process, reducing downtime and further improving productivity.

7. Easy to automate: metal disc etching plant equipment usually has a high degree of automation, can realize the automatic control of the production process. This makes it easier to realize the metal code plate etching processing and other production links of automation integration, improve the automation level of the entire production process.

8. Excellent electrical conductivity: metal disk has excellent electrical conductivity, can effectively reduce the resistance of the disk, improve the quality and stability of signal transmission. This is particularly important for the need to accurately transmit the signal incremental metal disk.

9. Good thermal stability: the metal material has a high thermal stability, so that the incremental metal disk in the high temperature environment can still maintain stable performance. This is important for the need to be used in a high temperature environment of the disk.

10. High strength and stiffness: metal materials have high strength and stiffness, so that the incremental metal disk can still maintain stable performance when subjected to large loads and vibration. This is important for the need to withstand large loads and vibration of the disk.

In summary, the choice of etching processing for incremental metal code discs has many advantages, including increased precision, improved quality, cost reduction, environmental protection and energy saving, adaptability, high efficiency, easy automation, excellent electrical conductivity, good thermal stability and high strength and stiffness. Therefore, metal codeplate etching processing is ideal for manufacturing incremental metal codeplates.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China