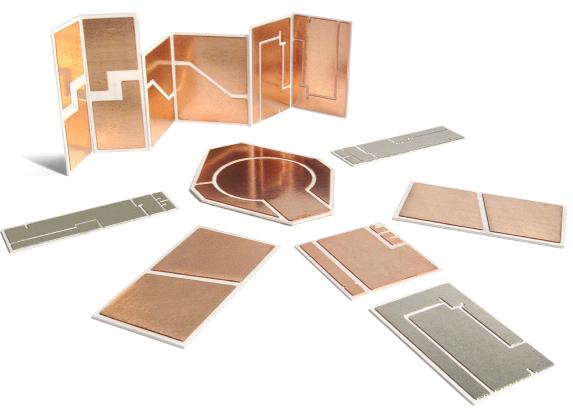

Ceramic copper-clad plate is a ceramic substrate (alumina or aluminum nitride) on the use of high-temperature firing process bonded copper foil composite materials, the main material can be used brass plate, phosphorus copper plate, beryllium copper plate, red copper plate, copper, copper, copper, copper, white copper and other copper materials. At present, the processing methods used mainly include laser cutting and punching, chemical plating, chemical etching and other processes.

Ceramic copper clad plate has high product characteristics, with high thermal conductivity and low coefficient of expansion, resistance to hot and cold cycle performance and mechanical strength, especially suitable for the current new energy automotive field of PCBA board design, the use of brake pads. Strong current conduction ability, wear and chemical corrosion resistance, processing out of the flatness and surface gloss is relatively high, not easy to bend deformation and warping. Has excellent product characteristics such as insulation voltage resistance.

In addition to ceramic copper cladding plate, there are glass copper cladding plate, ceramic copper cladding plate etching in addition to the new energy automotive applications, the important thing is that the high-power LED ceramic copper cladding heat dissipation substrate also has a good performance.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China