Stainless steel is a strong, corrosion-resistant material, making it a popular choice for a range of applications. Unlike glass or ceramics, however, stainless steel doesn't react with typical etching creams used for silicate-based materials. So, if you want to etch stainless steel for decorative or functional purposes, you'll need to use alternative techniques. Here, we’ll explore four primary methods to achieve etched designs on stainless steel surfaces: electrolytic etching, acid etching, laser etching or engraving, and engraving with a handheld tool.

Each method comes with its own requirements, costs, and levels of complexity, so let’s dive in!

How It Works: Electrolytic etching involves passing a small electric current through a solution, typically saltwater, to corrode the stainless steel in a controlled way. The process removes material from the surface, creating a permanent design.

Materials Needed:

A DC power supply (such as a battery or adapter)

Saltwater (a simple solution of salt and water)

Stencil (either vinyl or tape to cover areas you want to protect from etching)

Cotton swabs or a cloth

Leads and clips to connect the power supply to the metal

Instructions:

Prepare the Surface: Clean the stainless steel surface thoroughly, ensuring it is free from oils and debris. Apply your stencil or masking tape to create the design you want to etch.

Prepare the Electrolyte Solution: Mix salt in water to create a conductive solution.

Set Up the Circuit: Connect one lead from the DC power supply to the stainless steel (usually the positive). Attach the other lead to a cotton swab or cloth dipped in the saltwater solution.

Begin Etching: Rub the saltwater-soaked swab over the exposed areas of stainless steel while the current flows. The areas not covered by the stencil will begin to darken as the metal corrodes. You may need to go over the design several times for a deeper etch.

Finish Up: Once you achieve the desired depth, turn off the power, remove the stencil, and clean the steel to remove any residue.

Pros:

Cost-effective for DIY projects.

Relatively safe with household materials.

Effective for creating fine details.

Cons:

Time-consuming for larger areas.

Requires careful handling of electricity near water.

How It Works: Acid etching involves applying a strong acid, such as hydrochloric or nitric acid, to the stainless steel surface. The acid removes layers of steel, etching the exposed areas. This method requires more safety precautions due to the strength and corrosiveness of the acids involved.

Materials Needed:

Protective gear (gloves, goggles, mask, etc.)

Acid (hydrochloric or nitric acid)

Stencil or resist (vinyl or wax can work as a resist)

Plastic or glass container to hold the acid (do not use metal)

Instructions:

Prepare the Surface: Clean the stainless steel thoroughly. Apply a stencil or resist material to mask the areas that shouldn’t be etched.

Apply the Acid: Place the stainless steel in the acid solution or use a brush to apply it to the exposed areas. You may need to reapply the acid or leave the piece submerged, depending on how deep an etch you want.

Rinse and Neutralize: Once the desired etch is achieved, remove the steel from the acid and neutralize it with a baking soda and water solution. Rinse thoroughly with water and remove the resist or stencil.

Pros:

Quick and effective for deep etches.

Produces professional-looking results.

Cons:

Requires handling hazardous chemicals.

Acid disposal must be done responsibly.

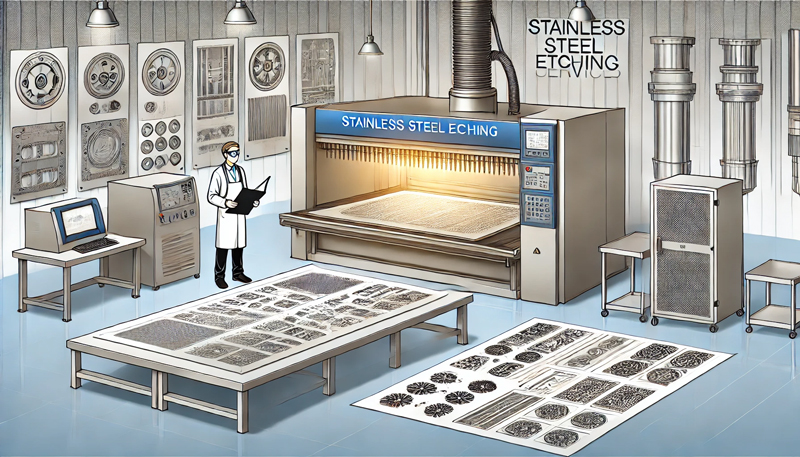

How It Works: Laser etching or engraving uses a focused laser beam to vaporize the stainless steel surface, creating a highly detailed design. This technique doesn’t require any chemicals, making it a cleaner option.

Materials Needed:

Laser engraving machine (CO2 or fiber laser, depending on the thickness and depth you need)

Instructions:

Prepare the Design: Use design software compatible with the laser engraver to create your pattern. Adjust the settings for stainless steel, specifying power, speed, and focus.

Place the Metal and Start Engraving: Secure the stainless steel in the machine, making sure it’s level. Follow the machine’s instructions and allow it to engrave your design.

Clean Up: Wipe the metal clean once the laser process is complete.

Pros:

Highly precise, suitable for complex designs.

No chemicals involved, making it safer and environmentally friendly.

Fast and efficient, especially for commercial use.

Cons:

Requires access to an engraving machine, which can be costly.

Limited to those with experience or access to industrial-grade tools.

How It Works: This manual technique involves physically engraving the metal with a handheld rotary tool or engraving pen. It’s ideal for small projects and personalized touches but requires a steady hand and patience.

Materials Needed:

Engraving pen or rotary tool (Dremel or similar brand)

Stencils (if needed) or freehand design

Safety goggles to protect from metal dust

Instructions:

Prepare the Surface: Clean the stainless steel and secure it in place. Use a stencil to guide your design or draw it freehand if you prefer.

Begin Engraving: Carefully trace your design with the engraving tool. Take breaks as needed to avoid hand fatigue, and go over any areas where you want a deeper or darker line.

Finish: Wipe away any dust, polish if desired, and clean the steel.

Pros:

Perfect for custom, small-scale designs.

No chemicals or power sources are needed.

Budget-friendly with just a few basic tools.

Cons:

Not suitable for large areas or highly detailed designs.

Requires manual skill and patience.

Your choice of method depends on your needs, budget, and comfort with the materials. Electrolytic etching and handheld engraving are more accessible and budget-friendly options for DIY enthusiasts. Laser engraving is an excellent choice if you have access to a laser machine and want precise, professional results. Acid etching, while effective, is best for those who have experience handling strong chemicals safely.

Each method brings unique qualities to the table, so weigh the pros and cons to decide which technique will best bring your Stainless steel etching project to life.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China