Etching stainless steel with ferric chloride is a common process used in metalworking to create intricate designs or patterns on the surface of the steel. Here’s a general guide on how to do it:

### Materials Needed

1. **Ferric Chloride Solution**: Available in various concentrations, typically around 40% for etching.

2. **Stainless Steel Item**: The piece you want to etch.

3. **Protective Gear**: Gloves, goggles, and a mask to protect from fumes.

4. **Resist Material**: This could be a vinyl stencil, permanent marker, or photoresist.

5. **Container**: A non-metallic container to hold the ferric chloride solution.

6. **Water**: For rinsing.

7. **Paper towels or cloth**: For cleaning and drying.

8. **Plastic tweezers or tongs**: To handle the item.

### Steps to Etch Stainless Steel

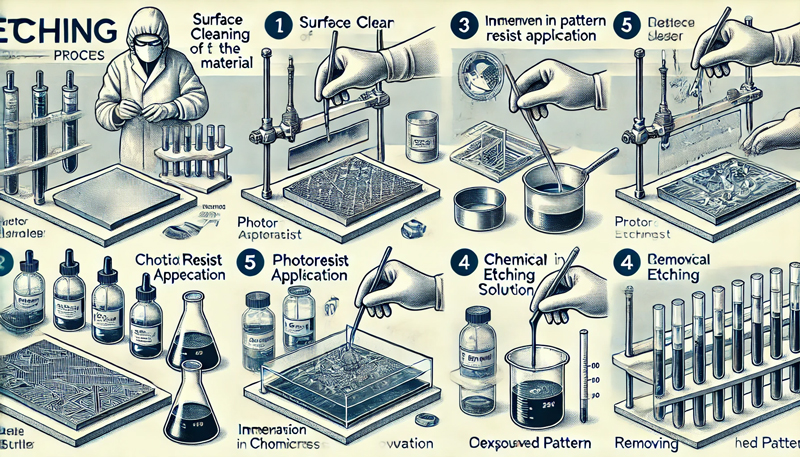

1. **Prepare the Surface**: Clean the stainless steel thoroughly to remove any oils, dirt, or residues. This can be done using soap and water or a degreaser.

2. **Apply Resist**: Cover the areas that you do not want to etch with your chosen resist material. If using a stencil, make sure it adheres well to prevent the ferric chloride from seeping underneath.

3. **Prepare Ferric Chloride Solution**: If using concentrated ferric chloride, dilute it to the desired concentration, if necessary. Follow the manufacturer's instructions for mixing.

4. **etching process**:

- Submerge the stainless steel piece in the ferric chloride solution. Ensure that the solution covers the areas to be etched.

- Let it sit for the required amount of time. This can vary from a few minutes to an hour, depending on the concentration of the solution and the depth of etch desired. Check periodically.

5. **Rinse**: Once the desired etching depth is achieved, remove the piece from the solution and rinse it thoroughly with water to stop the etching process.

6. **Remove Resist**: After rinsing, remove the resist material to reveal the etched design. You may need to use a solvent if you used a permanent marker or a more stubborn resist.

7. **Clean and Finish**: Clean the stainless steel piece again to remove any residues and dry it.

### Safety Precautions

- Always work in a well-ventilated area or under a fume hood, as ferric chloride can release harmful fumes.

- Wear appropriate protective gear to prevent skin contact and inhalation of fumes.

### Tips

- Test the process on a scrap piece of stainless steel first to determine the best timing and method for your specific project.

- If you want a deeper etch, you can repeat the process after cleaning the surface again.

By following these steps, you can achieve detailed and professional-looking etched designs on stainless steel using ferric chloride.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China