Etching cream is typically formulated for glass and can be challenging to use on stainless steel, which is much harder and more chemically resistant. However, if you’re looking to etch stainless steel, here are a few pointers:

Most commercially available etching creams, like those used on glass, won't work well on stainless steel. Instead, try ferric chloride or muriatic acid solutions, which are more effective for etching metals.

Ferric chloride is widely used for etching metals, especially stainless steel. It's available in liquid or powder form and is commonly used in electronics for PCB etching. Always dilute and handle it with care, as it can be hazardous.

Etching on stainless steel involves harsh chemicals, so take appropriate safety measures. Use gloves, protective eyewear, and work in a well-ventilated area or, ideally, outdoors.

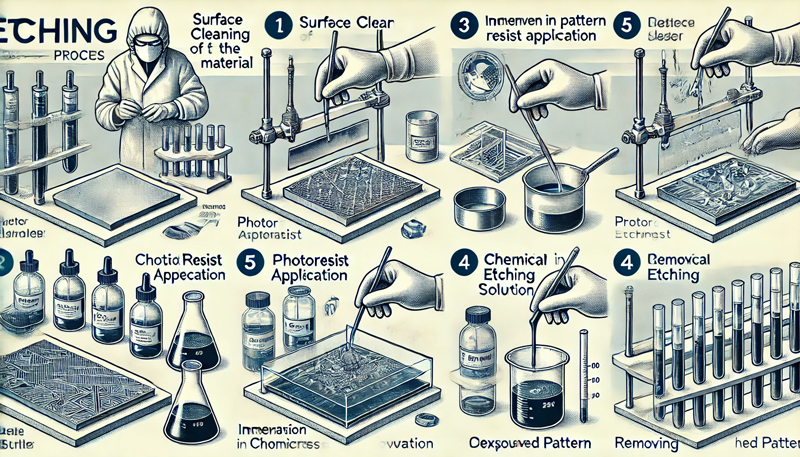

Clean the Metal Surface: Clean your stainless steel piece thoroughly to remove any grease or debris.

Apply Resist Material: Use a stencil, vinyl decal, or a specialized resist pen to mask the areas you don’t want etched.

Apply the Etching Solution: Brush or spray the ferric chloride or muriatic acid on the exposed areas, and let it sit for a few minutes.

Rinse and Remove Residue: After the desired etching time, rinse off the chemical and remove the resist material.

Electrolytic Etching: This involves using a saline solution and a small electrical current to etch designs into stainless steel. It’s popular for DIY projects and can be controlled more precisely than chemical etching.

These methods are generally more effective and safer for stainless steel than traditional etching creams meant for glass.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China