Etching on stainless steel is a process used to create designs, patterns, or markings on the surface of the metal. It involves using chemical solutions or

mechanical methods to remove material and produce a contrasting effect. Here’s a brief overview of the methods and applications of Stainless steel etching:

### Methods of Etching

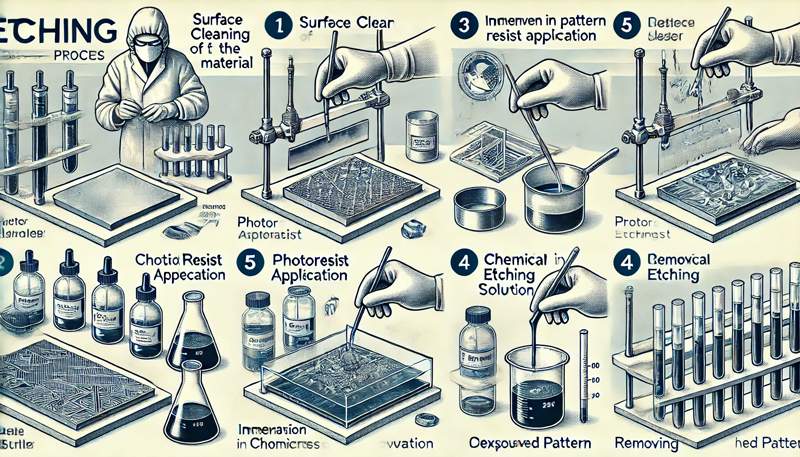

1. **Chemical Etching**:

- Involves applying an acid or a salt solution to the stainless steel surface to remove material.

- A photoresist can be used to cover areas that should not be etched, allowing for intricate designs.

- Common chemicals include ferric chloride or hydrochloric acid.

2. **Laser Etching**:

- Uses a laser to burn away the surface layer of stainless steel, creating a permanent mark.

- Offers high precision and can produce detailed designs quickly.

- Ideal for both small-scale and large-scale production.

3. **Electrolytic Etching**:

- Involves applying an electric current through an electrolyte solution to etch the surface.

- Often used for more precise and controlled designs.

4. **Mechanical Etching**:

- Utilizes tools like diamond-tipped engravers to physically remove material from the stainless steel.

- Suitable for less intricate designs and typically slower than chemical methods.

### Applications

- **Decorative Items**: Used in jewelry, art pieces, and architectural features.

- **Industrial Marking**: For part identification, barcodes, and logos.

- **Custom Products**: Personalization on items like trophies, gifts, and kitchenware.

### Advantages of Etching Stainless Steel

- **Durability**: Etched designs are resistant to wear and corrosion.

- **Aesthetic Appeal**: Can enhance the visual quality of stainless steel items.

- **Versatility**: Suitable for a wide range of applications across different industries.

### Safety Considerations

When etching stainless steel, especially with chemical methods, it's important to take safety precautions:

- Work in a well-ventilated area.

- Wear appropriate personal protective equipment (PPE), such as gloves and goggles.

- Properly dispose of any chemical waste according to local regulations.

If you have a specific project in mind or need tips on a particular etching technique, feel free to ask!

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China