Acid etching stainless steel is a process used to create designs, patterns, or textures on stainless steel surfaces. This technique involves applying a resist (a protective coating) to the areas of the steel surface that should remain unaffected, then exposing the metal to an acid solution that etches or corrodes unprotected areas. The process can be used in both decorative and industrial applications, like creating intricate designs on signs, panels, or artwork, and even for precision parts in manufacturing.

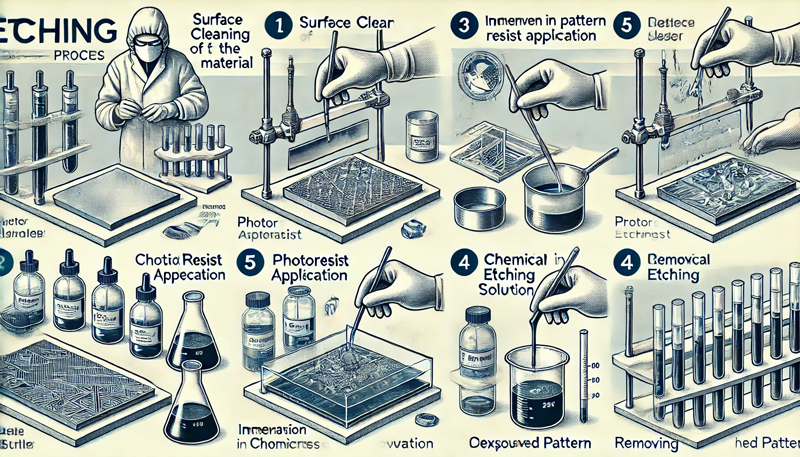

Here’s a basic overview of the acid etching process for stainless steel:

Clean the stainless steel surface to remove any oils, dirt, or contaminants, which can interfere with the etching.

A degreasing solution or a mild abrasive can help ensure the surface is completely clean.

The resist acts as a barrier to prevent the acid from etching certain areas of the metal.

Common resists include waxes, specialized resins, or tapes. Photographic resists can be used for more intricate designs.

This step is where you create the design, pattern, or texture by exposing the metal only in selected areas.

Once the resist is in place, the stainless steel is exposed to an acid solution. Hydrochloric acid or ferric chloride is typically used for stainless steel.

The acid reacts with the exposed areas of the metal, corroding and etching the design onto the surface.

The duration of exposure determines the depth of the etch; longer exposure produces a deeper etch.

After the desired etching depth is achieved, the acid is rinsed off, and a neutralizing solution is used to halt the chemical reaction.

Finally, the resist is removed, revealing the etched pattern on the stainless steel.

Always work in a well-ventilated area and wear appropriate personal protective equipment (PPE), such as gloves, goggles, and an acid-resistant apron.

Carefully handle and dispose of any acids and other chemicals involved, following local safety and environmental regulations.

Acid-etched stainless steel is popular in architectural elements, art installations, signage, kitchen equipment, and automotive trim. It can also be polished or colored for different visual effects, adding to its versatility in various design contexts.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China