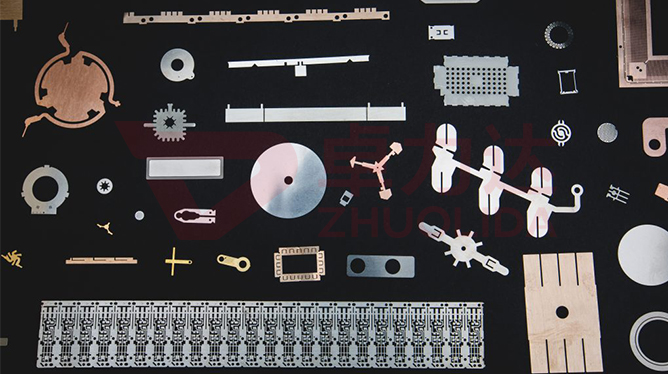

Etching is an important industrial manufacturing technique that is widely used in various industries and fields. This technique mainly involves the processes of chemical corrosion and physical etching, which can be used to manufacture various complex three-dimensional geometric shapes and fine structures. This article will introduce metal etching, Stainless steel etching and their application industries and fields in detail.

1. Metal etching :Metal etching is a technique for manufacturing metal products using chemical corrosion methods. This technique mainly uses specific chemical solutions to react with the metal surface to remove unnecessary metal materials. By precisely controlling the concentration and temperature of the corrosive liquid, as well as the shape and size of the metal product, high-precision metal product manufacturing can be achieved. In metal etching, the selection of appropriate corrosive liquid and processing conditions is very important. Different metal materials have different corrosion characteristics, so it is necessary to select appropriate corrosive liquid and process conditions according to the material type and processing requirements. In addition, environmental protection and safety production issues, such as waste liquid treatment and ventilation control, need to be paid attention to during metal etching.

2. Stainless steel etching :Stainless steel is a common metal material with excellent corrosion resistance and beautiful surface quality. Stainless steel etching is a technique for using chemical corrosion methods to process stainless steel materials into various products. Due to the high corrosion resistance and hardness of stainless steel, etching is required to be carried out on high-precision and high-efficiency processing equipment. The main steps of stainless steel etching include: first, cutting the stainless steel material into plates or pipes of the required shape and size; second, chemical corrosion treatment to remove unnecessary materials and form the required three-dimensional geometric shape; finally, surface treatment and cleaning to ensure the quality and appearance of the product.

3. Application industries and fields

(一)Microelectronics industry: Metal etching and stainless steel etching technologies are widely used in the microelectronics industry, such as manufacturing integrated circuits, thin-film solar cells, and micromotors. These technologies can produce high-precision, high-purity, and high-integration microelectronic devices.

(二)Medical device industry: Metal etching and stainless steel etching technologies can be used to manufacture medical devices, such as surgical instruments, dental instruments, and vascular interventional devices. These technologies can produce medical devices with high precision, high strength, and high corrosion resistance.

(三)Automotive industry: Metal etching and stainless steel etching technologies are widely used in the manufacturing of automotive parts. For example, these technologies can be used to manufacture high-precision, lightweight, and corrosion-resistant automotive parts, such as engine parts, chassis parts, and brake system parts.

(四)Aerospace industry: The aerospace field has very high requirements for the accuracy and performance of parts, and metal etching and stainless steel etching technologies are widely used in this field. For example, these technologies can be used to manufacture high-strength, lightweight, and corrosion-resistant aerospace parts, such as engine parts and fuselage structural parts.

(五)Optical industry: Metal etching and stainless steel etching technologies can be used to manufacture various optical components, such as lenses, reflectors, and filters. These technologies can produce optical components with high precision, high flatness, and corrosion resistance.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China