Electro-etching stainless steel is an advanced processing technology, which forms a concave-convex effect on the surface of stainless steel with a specific pattern or text through electrochemical principles, thus giving the stainless steel material unique aesthetic value and functional properties. Below, we will be from the principle of electro-etching stainless steel, process flow, application areas, advantages and future development, etc., on this technology for a detailed discussion.

First, let's understand the basic principle of electro-etching stainless steel. Electro etching is a processing technology that utilizes electrolysis to produce corrosion phenomena on the metal surface. In the electro-etching process, stainless steel as the anode, and the cathode to form an electrolytic cell between the electrolyte solution through the application of voltage, so that the ions in the electrolyte solution under the action of the electric field to migrate, so as to produce corrosion on the surface of stainless steel. By controlling the voltage, current density, electrolyte type and concentration and other parameters, the depth and shape of the corrosion can be accurately controlled, so as to obtain the desired pattern or text.

Next, we introduce the process flow of electro-etching stainless steel. First, the surface of the stainless steel needs to be pre-treated, including cleaning, polishing and degreasing steps to ensure that the surface is flat, smooth and free of oil. Then, a mask is made according to the design requirements to cover the part to be retained and only the area to be eroded is exposed. Next, the pre-treated stainless steel is placed into an electrolytic cell and the appropriate voltage and current density are applied for electro etching. After the electroetching is completed, the mask needs to be removed and the surface cleaned and dried. Finally, subsequent treatments such as coloring or polishing are applied to the etched area as needed to achieve the desired visual effect.

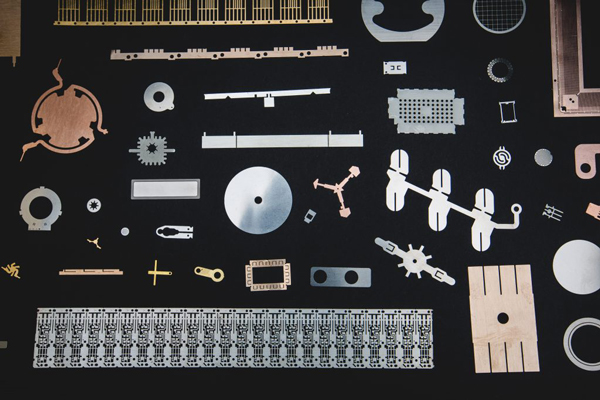

Electro-etched stainless steel has a wide range of applications in several fields. In the field of architecture, electro-etched stainless steel can be used to make decorative panels, screens, doors and windows, etc., adding a unique aesthetic charm to the building. In the field of industrial design, electro-etched stainless steel can be used to produce signage, nameplates, control panels, etc., to improve product recognition and experience. In addition, in the field of art production, jewelry processing, etc., electro-etched stainless steel also plays an important role, providing more creative possibilities for creators.

The advantage of electro-etched stainless steel lies in its unique processing effect and wide range of applications. Compared with traditional mechanical processing and chemical corrosion, electro-etching technology has higher precision and controllability, and can produce more delicate and complex patterns. At the same time, electro-etched stainless steel also has excellent corrosion and abrasion resistance, and can maintain long-lasting beauty and performance in harsh environments.

However, electro-etching stainless steel technology also faces some challenges and development direction. First of all, the electro-etching process requires precise control of various parameters, the operator's skills and experience requirements are high. Therefore, improving the degree of automation and intelligence is an important direction for the development of electro-etching technology. Secondly, with the growing awareness of environmental protection, the development of environmentally friendly electrolyte and reduce energy consumption is also an important research content of the electro-etching technology. In addition, the expansion of electro-etching stainless steel in new energy, environmental protection and other areas of application is also the future development trend.

In short, as an advanced processing technology, electro-etching stainless steel has a wide range of application prospects in many fields. With the continuous progress and innovation of technology, I believe that electro-etched stainless steel will play a greater role in the future, bringing more beauty and convenience to our lives.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China