Wet etching is a widely used technique in microelectronics manufacturing and integrated circuit fabrication, the main purpose of which is to form a desired pattern or structure on the surface of a specific material by means of chemical etching. This technique has played a crucial role in the development of modern electronics.

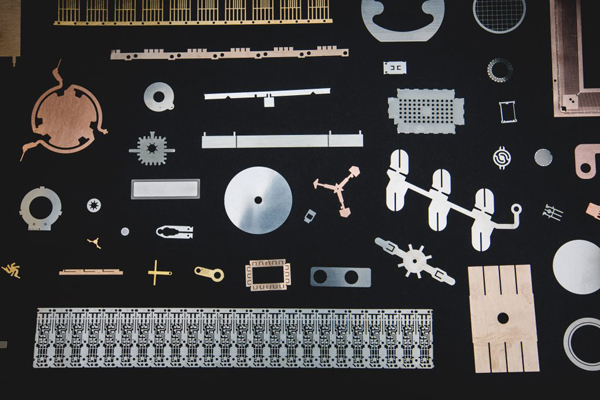

First of all, the core objective of wet etching is to microfabricate the material surface under precise control. By selectively removing portions of the material surface, wet etching can create a variety of complex structures and shapes. This is essential for the fabrication of high-performance electronic devices and integrated circuits. For example, wet etching is used in the semiconductor manufacturing process to form the precise structures of transistors, capacitors and other components.

Second, wet etching is a key means of achieving miniaturization and integration of microelectronic devices. With the progress of science and technology, the size of electronic devices is constantly shrinking and the integration degree is constantly improving. Wet etching technology meets the needs of this development trend with its high precision and flexibility. Through fine control of the etching process, complex structures and devices can be fabricated on the micron or even nanometer scale, thus greatly improving the performance and reliability of electronic devices.

In addition, wet etching technology is also economical. Compared with physical vapor deposition, photolithography and other microfabrication techniques, wet etching requires relatively low equipment and material costs. This makes wet etching in the field of microelectronics manufacturing has a wide range of application prospects. At the same time, wet etching technology is also constantly improving and optimizing to adapt to a wider range of applications.

In specific applications, wet etching technology also shows its unique advantages. For example, in the manufacture of three-dimensional microstructures, wet etching can realize precise control of the depth of the material surface by controlling factors such as the concentration of etchant, temperature and etching time. This makes wet etching valuable for a wide range of applications in fields such as biomedicine, sensors and micromechanical systems.

However, wet etching technology also faces some challenges and limitations. For example, side etching and undercutting that may occur during the etching process can affect the accuracy and integrity of the structure. In addition, the selection and handling of etching solutions place certain demands on environmental safety and personnel health. Therefore, when using wet etching technology, it is necessary to comprehensively consider a number of aspects such as process parameters, material properties and environmental factors to ensure the effectiveness and safety of the etching process.

In summary, wet etching, as an important microfabrication technology, is not only aimed at realizing the precise manufacturing and miniaturization of microelectronic devices, but also at promoting the progress and development of the entire microelectronics manufacturing industry. With the continuous progress and innovation of science and technology, wet etching technology will play a more important role in the future, bringing more convenience and progress for human society.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China