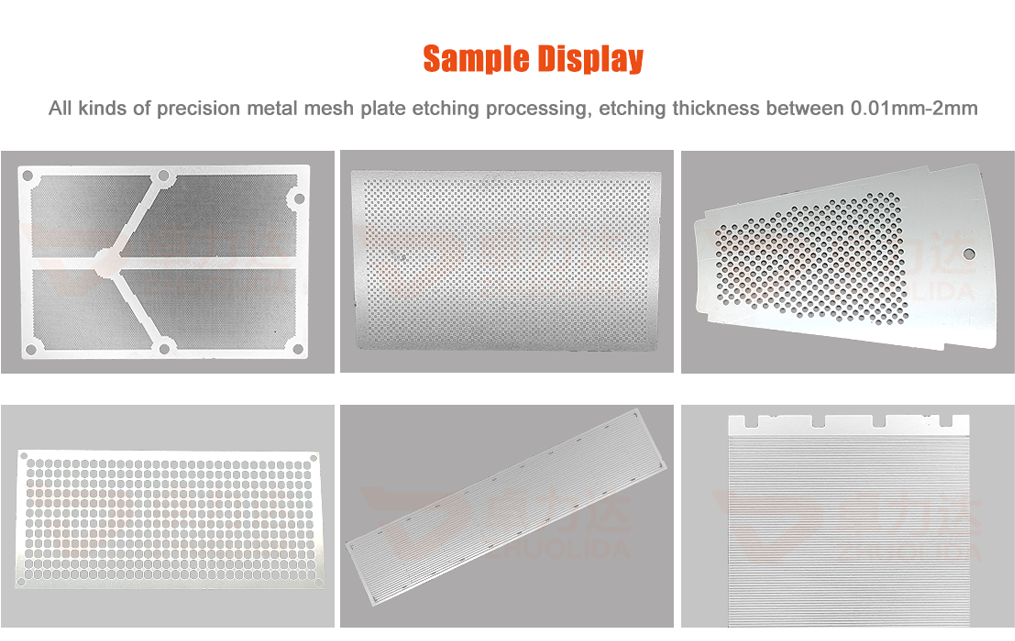

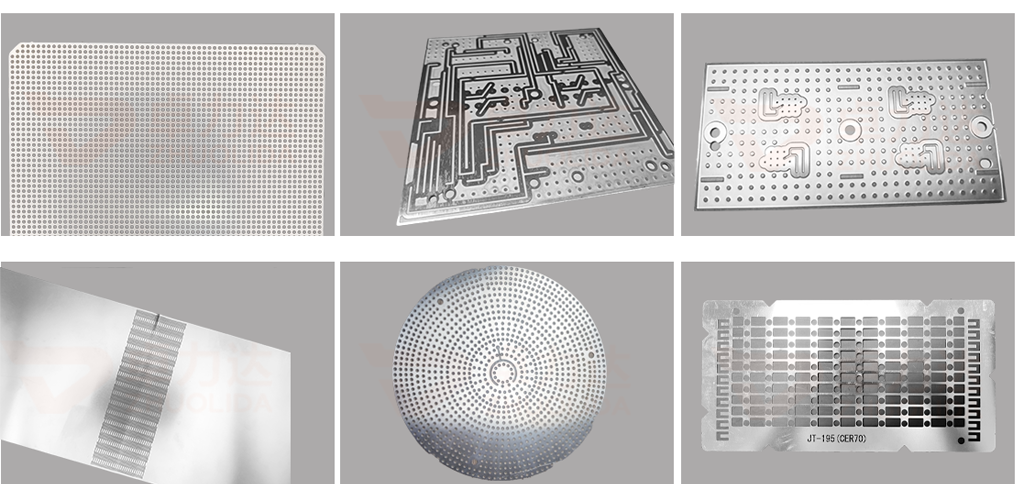

Product ID:Precision micro-hole etching process

Description:Mainly used for electronic, digital, optical and other precision parts products

| Material | Aluminum, Stainless Steel, Copper, Brass, or other metal |

| Size | According to your requirements |

| Thickness | Range from 0.02mm to 2.0mm or customized |

| Minimum Hole | 1.2 times by the thickness |

| Feature | Etched holes of uniform diameter, no burrs, no chips |

| Shape | Hexagon, oval, round, rectangle, square, or customized |

| Price | Depends on your materials, thickness, accuracy requirements and quantities etc |

| Sample | Paid samples within 3 days, the fastest in 24 hours |

| Production Capacity | Up to 10000 square meters per day,With roll-to-roll etching process for high volume production. |

| Lead Time | Normally within one week and depends on your order quantity |

| Product testing and after-sales. | Two-Dimensional, Imaging Instruments |

| Metal Etching characteristics & advantage: | |

| 1. Low mold cost, which can be arbitrarily changed according to the requirements of the designer with low cost. | |

| 2. It can be half etched on the metal components with your company LOGO for better brand identification | |

| 3. Extremely high precision, up to +/-0.0075mm accuracy, to meet the assembly requirements of different products. | |

| 4. Complex shape products can also be etched without additional cost | |

5. No burrs, no pressure points, products are not deformed, do not change the nature of the material, does not affect the function of the product | |

| 6. Both thick or thin materials can be etched in the same way to meet the requirements of different assembly components | |

| 7. Almost all metals can be etched, no restrictions on the design of various patterns | |

| 8. Even metal parts that can not be completed by various types of machining, it can be etched. | |

Etching processing of microporous filter mesh is a high-precision and high-efficiency processing technology, and its advantages are mainly manifested in the following aspects:

First of all, etching processing can accurately manufacture complex and fine microporous filters whose structures can be customized according to actual needs, providing a wide range of flexibility for a variety of applications. This high degree of customizability has led to the widespread use of microporous filters in a wide range of industries, including petroleum, chemical, food, and pharmaceutical.

Secondly, etching processing is a mass-production processing method that can efficiently manufacture large quantities of microporous filters. Compared with traditional machining or drilling technology, etching processing greatly improves production efficiency and reduces production costs while ensuring accuracy.

In addition, etching processing can also realize double-sided simultaneous processing, so that the front and back sides of the product can achieve the effect of smooth, no bumps, no pits, no burrs, no warping, and no deformation of the mesh is flat. This not only improves the aesthetics of the product, but also enhances its performance.

Finally, the etching process also has the characteristics of accurate positioning, uniformity and consistency, so that the aperture and spacing line width of the microporous filter mesh can be very fine, thus meeting the needs of high-precision filtration.

In summary, the microporous filter etching process in terms of precision, efficiency, aesthetics and wide range of applications have shown significant advantages for the development of various industries to provide strong support.

| Our Advantage | |

| Customer | |

| we are doing our best to provide our best services to our customers with competitive tech solutions and high quality products,Zhuolida has won wide recognition from our customers in all kinds of industry,and this have laid a solid foundation for Zhuolida to be an leading brand in etching industry in China and a reputable manufacturer! |

|

| Technology | |

| Zhuolida is an etching factory in China with varieties of process,our company process techniques include chemical etching,laser cutting,EDM,stamping electroforming,electroplating,electrophoresis. |

| Enviroment | |

| We have self-built sewage treatment system,the wastewaster reuse rate reaches 40% |

|

| Our Certifications |

| We are very aware of the standard management,in December 2004 our company has passed ISO9001 international quality system certification,in and July 2007 ISO 14001 environmental management system certification,the same year in December we joined Photo Chemical Machining institute(PCMI),in July 2016 we passed the ISO/TS16949 Automotive quality management system and in NovemBer 2016 formally received a National High-tech Enterprises certificate |

|

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China